SOAP PLODDER

CONVENTIONAL SOAP PLODDERS

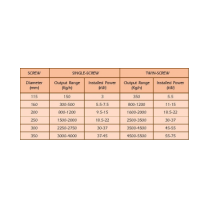

The majority of our soap plodders are customized units which are available with different layout combinations, different L/D (length to diameter) ratios, use of various materials, several and customized screw (soap worm) designs, multiple options and of course are offered in different sizes.

We also propose "Pelletizers", machines designed to transform soap of different size and shape into soap noodles for an optimal transportation and stocking.

Multi-colored systems for soap manufacturing are available in liquid-liquid, solid-liquid and solid-solid variations.

Besides the "conventional" soap plodders, we can offer the special TRANSAVON soap plodders with unique features, like the long L/D ratio "combo-screw" and the "soap milling valve". They are applicable for refining and extruding all types of soaps.

The SAS team is ready to share its expertise in proposing the most suitable soap plodders for your production requirements.

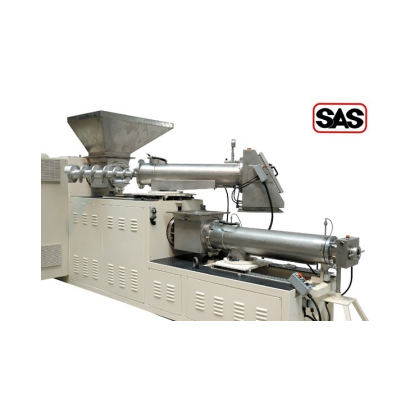

TRANSAVON SOAP PLODDER

The first "mission" of the Transavon project has been to provide an equipment suitable to efficiently control the critical "process" of the translucent soap finishing.

The possible applications were:

• Conversion of opaque soap noodles (pellets) into translucent soap

• Production of translucent extruded finished stamped bar soaps (tablets) using translucent noodles

After successful operation of Transavon Plodders for translucent noodles and bars and extensive testing of various products the Transavon plodders proved to be applicable for regular toilet soaps, soap/synthetic and synthetic products.

Plodders perform refining/homogenizing and compaction/extrusion functions the soap. The refining capability of a plodder depends on the L/D ratio (length of the barrel L to screw diameter D), the processing pressure and the mesh size of the refining screens. Transavon plodders have excellent refining capability compared with conventional refiner plodders.

Each Transavon refining stage is equivalent to 1.5 of a conventional modern refiner.

Transavon plodders are offered in the same 3 main types as regular plodders, namely: Simplex Refiner, Duplex Refiner, Duplex Vacuum Plodder.

The Duplex versions are available with two Transavon stages or combinations of a conventional plodder stage and a Transavon stage.

A PC-based logic process software control optimizes the variables in real-time. All Transavon Plodders are equipped with Variable Frequency Drives for wide screw rpm variation, Soap Pressure and Temperature Gauges; Automatic Cooling Water Controllers (Turboflow) units are seldom used.

Two novel features make the Transavon a unique plodder: the "COMBO-SCREW" and the "MILLING VALVE".

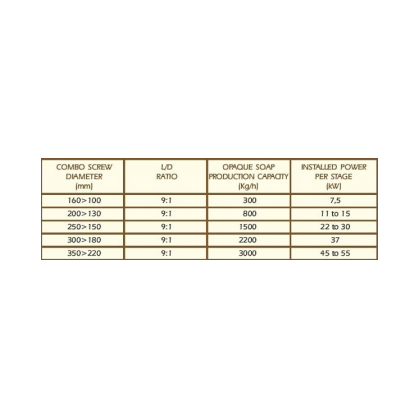

COMBO-SCREW

The Combo-Screw innovative design with two different diameters and an intermediate conical section optimizes the two main functions of plodder screws (worms):

1. Optimal soap infeed in the open section " This is obtained with a larger diameter short screw

2. Maximum homogenization and compression in the closed section " This is achieved with a small diameter and a 9:1 L/D screw (worm). This allows a constant and gradual increase of the soap pressure up to 100 bars when required.

Other benefits of the Combo-Screw are:

•The soap quantity processed is rather small due to the relatively small worm diameter allowing quick reaction to the change of process parameters.

•The heat exchange between soap and cooling water is optimized and for some products the soap temperature during passage in the plodder barrel a feature that is usually only obtained with the use of roll-mills.

•The high screw revolutions per minute (up to 50 rpm) gives to the soap a continuous shear effect and helps chemical and physical homogenization.

•Soap back-flow is drastically minimized.

•Screw cleaning is a simple operation thanks to the special "back extraction" system.

MILLING VALVE & SOAP PRESSURE CONTROL DURING PRODUCTION

The Milling Valve is a unique feature of the Transavon plodders. The device consists of two sliding slotted plates positioned at the end of the plodder. Adjustment to control the soap output can be made even during production. By controlling the soap passage, it is possible to adjust the soap processing pressure, thus the energy transferred to the soap by shear effect and the degree of refining.

Due to the special design of Milling Valve, when it is adjusted for a tight soap passage, the gap can be reduced down to 0.1 mm. The soap exits in very thin soap flakes. This milling effect eliminates or greatly reduces the dry specks (roughness, grit) present in some soaps.

The milled soap is then immediately re-compacted and it is ready to be pelletized or extruded depending by the down-stream device a drilled refining/palletizing group or an extrusion cone.

DOWNLOAD LEAFLET CONVENTIONAL SOAP PLODDERS

DOWNLOAD LEAFLET TRANSAVON PLODDERS