SOAP INFEED SYSTEMS

AUTOMATIC SOAP FEEDERS

One of our missions is to transform packaging machines such as Cartoners, Bundlers Flow Wrappers, previously used in different industrial applications, into “soap” machines.

A range of Soap Transfers of our design are available for any production need, from 100 to 500 soap bars per minute.

SOAP TRANSFER – 180 BPM (FOR SOAP CARTONERS & SOAP WRAPPERS)

The rotary torret with continuous movement consists of :

•Supporting frame with electric motor and Frequency Inverter

•Encoder and associated control for the synchronism with the soap packaging machine

•Group with 5 stations rotary carousel provided with rubber vacuum suction cups

•N. 2 Feed belts complete of soaps stop system actuated by photo-electric cell

•Accident prevention protecting system made of Plexiglass

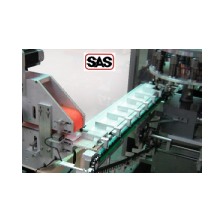

SOAP TRANSFER – 180 BPM (FOR SOAP FLOW WRAPPERS)

Device suitable to transfer soap bars coming from the soap press into the soap flow wrapper at a rate of 180 bpm. It consists of:

•a horizontal belt connecting conveyor driven by a frequency Inverrter

•a second horizontal slow-speed belt conveyor driven by a frequency inverter

•a pair of side belt conveyors driven by a Servo-driven motor

Such group is suitable to trasfer the soap bars with proper timing with the pushers present on the chain of the soap flow wrapper thanks to the detection of a photocell that should be assembled on the soap flow wrapper to pick the exact phase.

Except the photocell everything is stand-alone and interaction with the flow-wrapper are minimum.

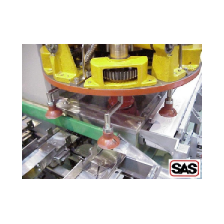

SOAP TRANSFER – 300 BPM (FOR SOAP CARTONERS & SOAP WRAPPERS)

Automatic “Pick & Place” Rotary Turret of original SAS design suitable to receive toilet soap bars on one lane arriving from the up-stream stamping machine and to feed a down-stream packaging machine. The group is complete with:

•Infeed conveyor driven by Frequency Inverter

•Indexed Rotary Turret complete with 8 suction-cups. The turret has eight stations, first station is pick-up of soap bar from infeed conveyor, then there is an idle station and third station is placing the bar in the bucket infeed chain of the cartoner. The group is mechanically linked to the cartoner

SOAP TRANSFER – 400 BPM (FOR SOAP CARTONERS)

Automatic “NON-CONTACT” soap transfer/feeder of original SAS design, suitable to receive toilet soap bars on one lane arriving from the up-stream stamping machine and to feed a down-stream packaging machine. The group is complete with:

•Set of three (3) Belt Conveyors (1: Connecting Conveyor, 2: Slow Speed Conveyor, 3 Alternate Timing Conveyor driven by brushless motor) to convey the soap bars in the Infeed Chain

•Infeed Chain mechanically connected with the packaging machine

•Belt Infeed Conveyor working in conjunction with the Infeed Chain

•Continuous Motion Infeed Rotary Turret with 12 suction-cups. The suction-cups pick the soap bars that are already in a controlled position and transfer to the bucket of the infeed chain of the cartoning machine. The group is mechanically linked to the packaging machine