TOILET SOAP STAMPING MACHINE

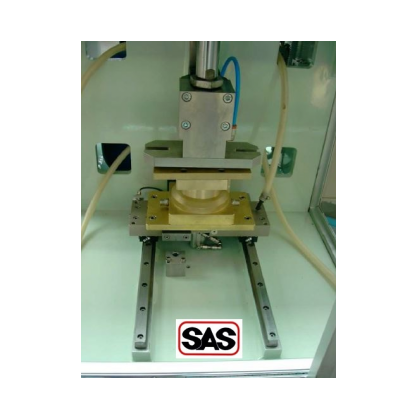

SAP SOAP PRESS

The SAP Semi-Automatic Soap Press has been designed to stamp banded soaps, bandless soaps and specialty shaped soap bars.

The SAP is a pneumatically operated unit specially suited for low production requirements, pilot plant and laboratory operations.

The lower die has two positions. A stamping position, under the upper die and a slug (billet) feeding and stamped bar (tablet) removal position on top of the lower die. This special feature permits a very safe, comfortable and easy operation.

MAIN FEATURES

•A compressed air cylinder (operated with 6 bar pressure) moves the upper soap die up and down vertically to meet the lower soap die. The soap mold according to stamped soap bar can be single, double or triple. The single die set produces one bar, the double two and the triple three bars for each stamping cycle.

•The bottom die after stamping moves forward for safe and easy removal of the stamped soap bar(s)

•Soap Stamped bar weight is easily controlled by mechanical adjustment of the clearance between the upper and lower dies. This feature also prevents any possible damage of the dies.

•Linear bearings are used to assure precise die movements.

OPERATION

•The front safety guard is opened. A precut soap slug (soap billet) is placed onto the lower die.

•To start a stamping cycle the operator must activate simultaneously with both hands two safety switches.

•The lower die group moves back and lines up with the upper die assembly.

•The upper die moves down meeting the lower die converting the unstamped slug into a stamped bar (tablet).

•The upper die raises.

•The front safety guard is opened manually. The lower die moves forward toward the operator and the stamped soap bar is removed.

•A new slug is placed onto the lower die and the safety guard is closed.

•A new stamping cycle starts.

DOWNLOAD LEAFLET SAP SOAP PRESS