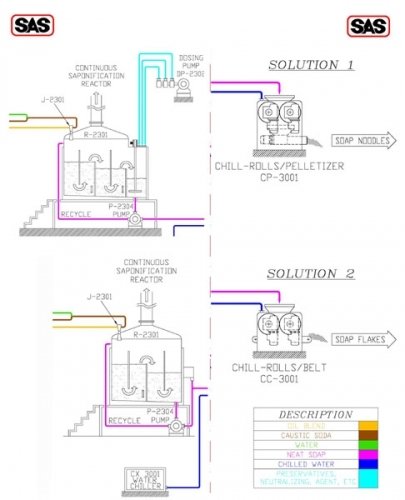

SOAP COOLING

DRUM FLAKER AND DRUM PELLETIZER

The Drum Flaker/Pelletizer (Chill Rolls) is a simple and reliable machine that cools and solidifies into flakes liquid neat soap, soap/syndet (“combo”) and syndet products.

It has a two special, counter-rotating stainless steel rolls equipped with internal cooling jacket to cool the soap.

Cold water is conveyed through in a spiral pattern all around the inner surface of the drum, to grant an uniform cooling transmission to the soap.

The drums are equipped with rotary joints for proper water distribution and consistent water recycling in a closed circuit when using a water chiller.

Separate motor-reducers drive each drum and the product discharge conveyor. These independent drives allow easy maintenance and flexibility of operation.

Liquid soap or syndet slurry is pumped on the rolls that spread it evenly among them, in a 0,3 – 0,5 mm thick layer that is quickly cooled down and solidified.

Soap is then scraped off the rolls, in form of soap flakes and fall onto a discharge conveyor belt or into the hopper of Pelletizer that produces soap noodles.

It is suitable to produce soap flakes / soap noodles at a temperature of 38-40°C approx. from liquid soap at 80-90°C.

Soap produced in this way has no dry specs, because of very limited drying involved.

Features:

•All parts in contact with soap made in AISI 304 stainless steel, remaining parts in epoxy painted carbon steel

•Gap Setting: mechanical manual setting and adjustment

•Connections: rotary joints

•Variable speed by Frecuency Inverter (only for Soap Pelletizer)

DOWNLOAD LEAFLET CHILL ROLLS